* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Project Draft 1: High Sensitivity, Very Low Drift Temperature Sensor

Electrical substation wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Current source wikipedia , lookup

Stray voltage wikipedia , lookup

Thermal runaway wikipedia , lookup

Schmitt trigger wikipedia , lookup

Control system wikipedia , lookup

Analog-to-digital converter wikipedia , lookup

Buck converter wikipedia , lookup

Alternating current wikipedia , lookup

Voltage optimisation wikipedia , lookup

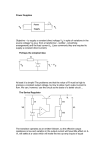

Lumped element model wikipedia , lookup

Switched-mode power supply wikipedia , lookup

Mains electricity wikipedia , lookup

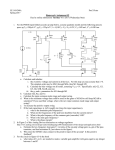

Project Draft 1: High Sensitivity, Very Low Drift Temperature Sensor With Digitized Output Through their constant miniaturization and increasing accuracy, temperature sensors are starting to be used in an increasing number of unique medical and environmental applications. The integration of RFID tags with temperature sensors provides wireless temperature sensing capabilities, which is useful in, for example, monitoring the temperature of perishable food [1]. However the challenge with such portability arises in maintaining accuracy despite low power constraints. Accurate wireless body temperature monitoring has been successfully achieved, but only in a limited range, from 35°C to 45°C [2]. A wider range with an accuracy of ±0.1°C would be desirable in order to extend the usefulness of the RFID based temperature sensor to environmental applications in order to supplement humidity and pressure data with temperature measurements [3]. Thus, the development of an accurate temperature sensor with a wide sensing range is important because it would not only enable its use in the previously mentioned applications, but can also "open up new applications in the medical, industrial, automotive, and consumer fields" [4]. A proposed top level system block diagram for the design of the temperature sensor is shown below in Figure 1. Figure 1. System level block diagram for proposed temperature sensor integrated circuit. All of the components for the proposed temperature sensor will be entirely on-chip except for the clock signal used to drive the 14-bit ADC. The clock signal, for example, may be received from a crystal oscillator located on the same PCB. A temperature independent band-gap reference (BGR) of 1.2 V will be used for the ADC and may also be used for the temperature sensor and the auto-zeroing operational amplifier (op-amp) configurations. Since the device will be used in extreme temperature conditions, a BGR is necessary to ensure stable circuit operation. The temperature sensor will generate a proportional to absolute temperature (PTAT) voltage output. The PTAT voltage output will first be fed through an auto-zeroing op-amp configuration. This particular op-amp configuration enforces stability to eliminate errors associated with temperature drift and with the offset voltages associated with the op-amps themselves. Finally, the output of the op-amp configuration is used by the ADC to generate a digital output. A special second order ADC is utilized to achieve high accuracy and low power consumption. A standard BGR will be used to create a temperature independent voltage reference off of which some or all of the other blocks will operate. The input to the BGR is the supply voltage and the output is the 1.2 V reference voltage. The temperature sensing circuit, adopted from Makinawa, will have two identical substrate PNP bipolar transistors with a collector current ratio set to 1:p, due to a PMOS current mirror load [4]. As a result, the ∆VEB of the PNP transistors equals (kT/q)*ln(p), which is a PTAT voltage since it is linearly proportional to the temperature. The temperature sensing circuit described can be seen in Figure 2. The input for the temperature sensing circuit is a simple bias voltage for the PMOS current mirror and the output is a PTAT voltage or current [4]. Figure 2. Basic schematic of temperature sensing circuit [4]. The op-amp that will be used with the temperature sensing circuit to reduce the temperature drift of the PTAT voltage or current will be an auto-zeroing operational amplifier. This type of operational amplifier will be used since the offset voltage of the amplifier can be reduced by a factor of up to 500 [5]. Figure 3 shows a diagram of an auto-zeroing op-amp configuration that can be used to nullify the effects of the offset voltage. Essentially, a nulling amplifier is inserted along with the wideband amplifier so that the offset calibration path is in parallel with the signal path. With a clock signal, the circuit will be in two phases in a clock cycle: the auto-zero phase and the signal amplification phase [5]. Figure 3. Diagram of the auto-zeroing op-amp configuration [5]. The input of the block includes bias voltages and currents, the PTAT voltage, and a clock signal for the switches if an on-chip oscillator cannot be implemented. The output of the op-amp is an output voltage with a low offset. The proposed design of the ADC uses the zoom-ADC topology implemented by Makinawa. Since temperature sensing applications do not generally require high-speed performance, the disadvantage of increased computational time from the multiple steps employed by the zoom-ADC is trivial compared to the high resolution and accuracy that the topology offers. The coarse stage of the ADC will use a 5-bit SAR to determine the integer value of the VBE/∆VBE ratio (these values are input from the temperature sensor), as seen in Figure 4a [6]. The fine stage will then determine the fractional component of the ratio and convert it into a 9-bit digital signal. This stage is implemented with a Σ∆-ADC, represented in Figure 4b. This stage is designed to be second-order due to the lower power consumption of two low-gain integrators compared to the single, high-gain integrator of a first-order design. The op-amps used for the integrators in this stage should be designed for low power consumption and relatively high gain, which can be provided by a telescopic op-amp [6]. Figure 4. Block diagrams of the coarse (a) and fine (b) ADC topologies [6]. The proposed system will be implemented with the 0.5-µm standard CMOS process, which will use a supply voltage of 3 V. Many current temperature sensing circuits function in the 1-2 V supply range and can therefore achieve low power consumption; however, the proposed design will aim for about 800 µW of power consumption as a reasonable benchmark to achieve the desired resolution and accuracy with a 3 V supply. For this low power design, it would be practical to implement the ADC with 14 bits, which provides enough resolution within the range of operating temperatures and does not require a large supply voltage. A benchmarking table that provides a comparison between our proposed design and the state of the art design is shown in Table 1. Table 1. Comparison of State-of-the-Art and Proposed Specifications State-of-the-Art Design [4] Proposed Design 14 ~13 Number of Bits .1 °C .022 °C Resolution 800 µW ~300 µW Power Consumption -40° - 125°C -55° - 125°C Temperature Range ±.2 °C ±.15 °C Accuracy 3V 1.5 V – 2 V Supply Voltage Table 2 provides a proposed list of tasks that need to be accomplished and the group members responsible for them. Table 2. Proposed Delegation of Tasks to Group Members Task Draft 2 System Level and Circuit Simulation -Voltage Reference -Temperature Sensor -Auto-Zeroing Op-Amp Configuration -Zoom-ADC Design Review Layout (Zoom-ADC) Post Layout Simulation (Zoom-ADC) Final Presentation Final Paper Team Member(s) Responsible All Samrat Ankur Jeff All All Samrat, Ankur Jeff All All References: [1] M. Law, A. Bermark, and H. C. Luong, “A sub- µW embedded temperature sensor for RFID food monitoring application,” IEEE J. Solid-State Circuits, vol. 45, no. 6, pp. 1246–1255, Dec. 2010. [2] A. Vaz et al., “Full passive UHF tag with a temperature sensor suitable for human body temperature monitoring,” IEEE Trans. Circuits Syst. II, vol. 57, no. 2, pp. 95–99, Feb. 2010. [3] H. Shen, L. Li, and Y. Zhou, “Fully integrated passive UHF RFID tag with temperature sensor for environment monitoring,” in Proc. 7th Int. Conf. ASIC, Oct. 2007, pp. 360–363. [4] Souri, K.; Youngcheol Chae; Makinwa, K.A.A., "A CMOS Temperature Sensor With a VoltageCalibrated Inaccuracy of ±0.15°C (3σ) From 55°C to 125°C," IEEE J. Solid-State Circuits, vol.48, no.1, pp.292-301, Jan. 2013 [5] Kugelstadt, Thomas, “Auto-zero amplifiers ease the design of high-precision circuits,” Amplifiers: Op Amps, Texas Instruments Inc, Texas, Tech. Rep, 2005. [6] K. Souri and K. A. A. Makinwa, “A 0.12 mm 7.4 W micropower temperature sensor with an inaccuracy of ±0.2°C from -30°C to 125°C,” IEEE J. Solid-State Circuits, vol. 46, no. 7, pp. 1693–1700, Jul. 2011.