* Your assessment is very important for improving the workof artificial intelligence, which forms the content of this project

Download A DSP based reliable fuel cell power system with input

Power engineering wikipedia , lookup

Voltage optimisation wikipedia , lookup

Current source wikipedia , lookup

Mercury-arc valve wikipedia , lookup

Mains electricity wikipedia , lookup

Variable-frequency drive wikipedia , lookup

Opto-isolator wikipedia , lookup

Power inverter wikipedia , lookup

Pulse-width modulation wikipedia , lookup

Alternating current wikipedia , lookup

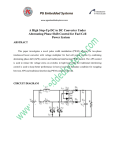

International Journal on Advanced Computer Theory and Engineering (IJACTE) “CONTROL FOR RELIABLE FUEL CELL POWER SYSTEM WITH INPUT RIPPLE CURRENT COMPENSATION”OVERVIEW 1 Sachin N.Phad, 2 A.M.Jain 1 Student of Master of Engineering K.K.Wagh College of Engineering & Research Centre Nasik. 2 K.K.Wagh College of Engineering & Research Center, Nashik Email: - sachinphad83@rediffmail.com Abstract: This paper work is carried out to reduce ripple current which is flow to the fuel cell/Battery through power electronics devices during dc-ac operation. FCs have advantages such as high efficiency, zero or low emission (of pollutant gases), and flexible modular structure With clean operating environment and high energy conversion efficiency, fuel cell is getting more and more attention, especially for the stationary power application. Such an application, either delivering electricity with utility intertie or directly supplying to residential area as a standalone power source, can be used for future distributed generation systems Figure 1 :- Block diagram of a stationary fuel cell power system Some existing commercial-off-the-shelf proton exchange membrane (PEM) fuel cells also have their nominal voltage set at 48 V and below for either telecommunication or residential applications. In order for low voltage dc fuel cell to generate 50/60 Hz, 120/240 V ac voltage for residential applications, a dc– dc converter is needed to boost the fuel cell voltage to a level that can be converted to the desired ac output. Fig. 1 shows such a system structure that contains a low-voltage high-current dc–dc converter and a dc–ac inverter. The output of the dc– dc converter, or the input of the dc–ac inverter for 120 V ac is typically 200 V; and for 240 V ac is about 400 V. For a nominal 20 V, 5 kW fuel cell under full load condition, the voltage is 20 V, and the average current is 250 A. The ripple is added on top of the average current with a peak current that tends to overload the fuel cell periodically. The fuel cell can experience nuisance tripping with such a ripple related overload situation. This paper initially describes problems associated with the fuel cell due to the ripple current such a ripple current may shorten fuel cell life span and worsen the fuel efficiency due to the hysteresis effect. The most obvious impact is it tends to reduce the fuel cell output capacity because the fuel cell controller trips under instantaneous over-current condition. I section two different methods are discuss , I section three appropriate method is discuss & i section four conclusion is given. This paper consists of different methods through which the ripple current analyses and control. Keywords: Fuel cell, Ripple current, dcac conversion, active filter, power electronics I. INTRODUCTION Fuel cells (FCs) are static electric power sources that convert the chemical energy of fuel directly into electrical energy. FCs have advantages such as high efficiency, zero or low emission (of pollutant gases), and flexible modular st FCs are good energy sources to provide reliable power at steady state; however, due to their slow internal electrochemical and thermodynamic characteristics, they cannot respond to electrical load transients as quickly as desired.[1] .They are connected to the power grid through power electronic interfacing devices, and it is possible to control their performance by controlling the interfacing devices. Modelling of FCs can therefore be helpful in evaluating their performance and for designing controllers [1,2]. Figure 2 :- Block diagram of ripple current generation in fuel cell power system II. METHODOLOGY ISSN (Print) : 2319 – 2526, Volume-2, Issue-6, 2013 26 International Journal on Advanced Computer Theory and Engineering (IJACTE) Some approaches have been proposed to prevent this 120 Hz ripple from being imposed on the fuel cell. One of the methods proposed [3] uses a LC series response circuit tuned to twice the output frequency connected in parallel to the DC bus capacitor in a composite PWM voltage source inverter. This approach requires bulky components. A multiloop control for a high frequency link DC-AC inverter system is proposed in [4]. Another topology using a high frequency link and an active filter is proposed in [5]. The high frequency link necessities the use of a high frequency transformer and other switching devices. Method using an active filter for current ripple reduction was proposed in [6, 7]. However these methods are based on using a separate energy storing device like battery or ultra capacitor. capacitor or a passive L-C filter circuit is generally connected to the DC line in order to reduce low frequency ripple voltage. Furthermore, when batteries are connected to the DC output., most of the DC ripple current generated by the PWM converter flows into the battery because the impedance of the battery is comparatively much lower than that of the prior-art circuit Battery ripple current particularly at low frequencies, results in battery heating and a corresponding rise in temperature. It is well known that battery life time decreases as temperature increases. Method -1 The present paper introduces a new topology for a single phase PWM voltage source converter which produces not only sinusoidal input current but also zero ripple output current This new topology is accomplished by adding only a pair of switching devices and a reactor to a conventional single-phase PWM converter circuit. Using a simple control technique, the ripple energy in the DC line is converted by the action of the additional switches into energy which is stored in the additional inductor. Fig.3 shows the configuration of the main circuit of the proposed PWM converter. Adding energy storage capacitor either on the high-side dc bus or on the low side fuel cell dc bus may help reduce the ripple, but the cost and size of added energy storage component are objectionable when the ripple is reduced to an acceptable range. Laboratory test indicated a peak-to-peak Ripple of 34% is obtained with a typical 1.2- kW design. This Ripple current component implies that fuel cell requires a power handling capability 17% higher than its nominal output rating. Current ripple not only affects the fuel cell capacity, but also the fuel consumption and life span [2], [3]. The results indicate that the fuel cell not only needs higher power handling capability, but also consumes 10% more fuels [2]. Furthermore, as pointed out by [3], the 100-Hz harmonic current exhibits a hysteresis Behavior with PEM fuel cells. Injecting ripple current around this frequency to fuel cell may result in thermal problem among stacks and impair the stack lifetime. Figure 3 :-Low frequency ripple current generation y single phase full-ridge inverter The fuel cell current Ripple reduction is thus a major issue for the fuel cell converter Design. Reference [4] suggested that the ripple current be limited to less than 10%. Passive energy storage compensation Method was suggested and tested extensively in [5]. Active Compensation with external bidirectional dc–dc converter method was suggested in [6], [7]. These methods require externally Added components or circuits and are not preferred a] The rectifier portion of the single phase PWM converter consists of U-phase switches (SI, Sz), Vphase switches (S9,S4), a DC capacitor (CO),a and an input AC filter circuit (LAC, CAC). The ripple reducing portion consists of additional switches (S5, s6) which we call W- phase switches, V phase switches which are shared with the rectifier portion, and an additional inductor (Lw) that is connected between the junction of the V-phase switches and the junction of the W-phase switches. DC Ripple Current Reduction Method on A Single Phase PWM Voltage Source Converter The generation of harmonics and their subsequent propagation into utility lines is a topic of increasing concern for power supply authorities. To reduce harmonics in power lines, unity power factor PWM converters are used. However, single phase PWM converters have serious defects including low frequency ripple current which appears on the DC output increases in proportion to the input current into the PWM converter, resulting in low frequency ripple voltage in the DC output Therefore, a very large Figure 4 :-Modulation principle. ISSN (Print) : 2319 – 2526, Volume-2, Issue-6, 2013 27 International Journal on Advanced Computer Theory and Engineering (IJACTE) Figure 8 :- Equivalent circuit of the ripple reducing portion Operation principle A Rectifier Portion For PWM modulation in the rectifier portion and ripple reducing portion, a triangular signal with a frequency of 20kHz is used in common. The switching frequency of switches S1 - s6 is then comparatively higher than the AC input frequency. Fig.4&5 shows the waveforms of the & signals U t ~ i and control signals Vu and Vv. Fig 5 shows the detailed waveforms of Vtri, Vu, and Vv during one switching period. SI and S2 are controlled based on a comparison of Vu and Ubi, and .S3 and S4 are controlled based on a comparison of Vv and Vtri. Hence, the "ON duty factor" Du of S1 and the "ON duty factor" Dv of S3 are defined as shown in Fig.3. Depending on the combination of Du and Dv, switching stages, stage 6a stage 6a, of the main circuit of the rectifier portion are defined and the switching sequence during one switching period is determined. Fig 6 (a) - (c) show the equivalent circuits that correspond to each stage. AC input current icr flows into the DC output in stage2a, but circulates in the switching devices in stages la and IC Figure 5 :- Switching stages of the rectifier portion. B. Ripple Reducing Portion In order to reduce the DC ripple current, both V- phase and W- Phase switches are used. Similar to the rectifier portion, the "ON duty factor" Dw of S5 is defined and switching stages, stage lb - stage4b, of the ripple reducing circuit Figure 6 :- Equivalent circuit of the rectifier portion III. DSP BASED CONTROL Method 2 In this a mathematical analysis of a single phase inverter has been presented to verify the appearance of the second harmonics current ripple at the inverter stage. An active filter method to cancel the second harmonics current ripple drawn from the fuel cell source in a single phase fuel cell system is proposed. Texas instrument DSP TMS 320 F 2808 is used for the overall control and monitoring of the system. Figure 7:- Switching stages of the ripple redwing portion Block diagram of the proposed system and the second harmonic current flow ISSN (Print) : 2319 – 2526, Volume-2, Issue-6, 2013 28 International Journal on Advanced Computer Theory and Engineering (IJACTE) Figure 9 :- Block diagram of the proposed system and the second harmonic current flow component at 120 Hz. The total ripple factor is around 55%. For the proposed system with DC bus voltage 25V the amplitude of the DC component of the fuel cell current around 1.9A. Figure 9 shows the proposed system block diagram along with the second harmonics current path . The proposed system uses an active filter connected across the DC-DC converter. The active filter provides an alternate path for the second harmonics current and prevents the ripple to appear on the fuel cell side. The active filter block consists of two controllable switches and an inductor. When using DSP based control, these two switches can be controlled easily using the same DSP chip used for the control of the inverter and/ or boost switches. The second harmonics current component now flows from the inverter through the boost circuit into the active filter and back to the inverter. IV. CONCLUSION Table 1 : -Comparison between convectional system & proposed system Quantity Conventional Proposed System System Vdc (Bus Voltage) 25V 25V 1 fuel cell 0Hz (DC 2A 1.9A Current drawn) 1fuel-cell @120 Hz (120 1.2A 0.6A Hz ripple current imposed on the fuel cell) Ripple factor due to 120 50% 29.5% Hz current Total Ripple factor >55.7% <36% A DSP based reliable fuel cell power system with input ripple current compensation using an active filter is presented. The proposed system provide an alternate path for the ripple current through the active filter which prevent the ripple current from circulating through the fuel cell source. The cancellation current is derived from the DC bus capacitor itself and hence no external energy storing device is required. IV. REFERENCES Figure 10 :- Current Ripple Under Dynamic Condition without Adding Capacitors Figure 11 :- proposed filter operation Fuel cell voltage, fuel cell current Figure 12 :- Simulation results for the proposed system; (a)Fuel cell current and output current For a convectional system with DC us voltage of 25V the amplitude of the DC component of the fuel cell current is around 2A. There is a significant ripple [1] T Shimh, T.Fqiita, G Ximura, J Xirme, "unity power factor PWM converter with DC ripples compensation" Trans. on IEE of Japan, D- 117, Vd.4, pp.434-442, 1997. (Im Japanese [2] “EG&G Technical Services, Inc. Science Applications International Corporation,” in Fuel Cell Handbook, 6th ed. vol. DOE/NETL- 2002/ 1179, Nov. 2002. [3] W. Choi, P. N. Enjeti, and J. W. Howze, “Development of an equivalent Circuit model of a fuel cell to evaluate the effects of inverter ripple Current,” in Proc. IEEE Applied Power Electronics Conf. and Expo. Feb. 2004, pp. 355–361. [4] G. Fontes, C. Turpin, R. Saisset, T. Meynard, and S. Astier, “Interactions Between fuel cells and power converters influence of current Harmonics on a fuel cell stack,” in Proc. IEEE Power Electronics Specialists Conf., Aachen, Germany, Jun. 2004, pp. 4729–4735. [5] R. S. Gemmen, “Analysis for the effect of inverter ripple current on fuel Cell operating condition,” J. Fluids Eng., vol. 125, no. 3, pp. 576– 585, 2003 ISSN (Print) : 2319 – 2526, Volume-2, Issue-6, 2013 29 International Journal on Advanced Computer Theory and Engineering (IJACTE) [6] M. Schenck, K. Stanton, and J. S. Lai, “Fuel cell and power conditioning system interactions,” in Proc. IEEE Applied Power Electronics Conf., Austin, TX, Mar. 2005, pp. 114–120. [7] Y. R. Novaes and I. Barbi, “Low frequency ripple current elimination In fuel cell systems,” in Proc. Fuel Seminar Special Session on Fuel Cell Power Conditioning, Miami, FL, 2003, pp. 21–27. [8] DSP based control for reliable fuel cell power system with input ripple current compensation IEEE 2008 ISSN (Print) : 2319 – 2526, Volume-2, Issue-6, 2013 30