* Your assessment is very important for improving the work of artificial intelligence, which forms the content of this project

Download Fuel cells are one of the most promising technologies for delivering

Survey

Document related concepts

Transcript

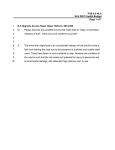

Capabilities that deliver reliable monitoring and control, as well as offer the benefit of a flexible configuration, are critical to keep pace with evolving fuel-cell technology, according to National Instruments. F uel cells are one of the most promising technologies for delivering clean and efficient power for A Ballard fuel-cell stack being tested prior to shipment. automotive and residential applications. A fuel cell directly converts the chemical energy of hydrogen and oxygen into electricity with a byproduct of pure water. Until recently, fuel cells have largely been restricted to NASA space missions and a few research labs around the world. However, with increased urgency in reducing pollution and greenhouse gas emissions, a resurgence of interest in fuel cells has occurred in the scientific community. Today, governments and large corporations are making massive investments into the development of these clean power sources. Although fuel cells hold great promise for clean, inexpensive power, they are still in their developmental infancy, and a great deal of research is necessary before they are considered viable power systems. Test capabilities that deliver reliable monitoring and control, and offer the benefit of a flexible configuration, are critical to these advances. The capabilities will permit scientists to easily tailor their systems to keep pace with evolving fuel-cell technology. aei MARCH 2001 85 as seen in Fuel-cell testing Even though several types of fuel cells exist, they all work under the same basic premise of converting hydrogen and oxygen into electrical power. Of the fuel-cell technologies, which include alkaline (AFC), molten carbonate (MC), phosphoric acid (PAFC), proton exchange membrane (PEM), and solid oxide (SOFC), PEM is gaining most of the attention in automotive applications. PEMs are popular due to their relatively low operating temperature and high efficiency. The PEM fuel cell operates by using platinum-coated membranes as a catalyst to break a hydrogen atom into a proton and an electron. The membrane is permeable to protons, but impenetrable to free electrons. These electrons are forced to travel through an electric circuit before they rejoin with free protons and oxygen molecules to form water. In this way, the anode of the fuel cell produces electricity, and the cathode creates heat and water. However, just as it took years of tests and improvements to achieve the efficiencies currently realized by internal combustion engines, many improvements are necessary before fuel cells are viable for automotive use. efficiencies of next-generation fuel cells, engineers are constantly incorporating new measurements into their tests and demanding reliable, accurate, and flexible test systems. Testing a fuel cell Because fuel cells are still in the development stage, the automotive industry has not settled on standard testing equipment or test-equipment vendors. Many companies are stepping up to the challenge of developing both modular and turnkey solutions to accurately monitor and control fuel cells. Notable among these companies are Hydrogenics and National Instru- Electricity Oxygen (O2) Anode (-) Cathode (+) Figure 2. Virginia Tech engineering students prepare a PEM fuel cell for use in their hybrid-electric Chevrolet Lumina for the 1999 Future Car Challenge. Hydrogen (H2) Courtesy of Hydrogenics Water Heat Proton exchange membrane Figure 1. Electricity generated in a Proton Exchange Membrane (PEM) fuel cell. The introduction of computer control revolutionized the internal combustion engine. It allowed engineers to monitor and control fuel rate, timing, and cooling. With the adoption of monitoring and controlling techniques such as fuel injection, oxygen sensors, knock detectors, and mass flow sensors, engine efficiencies have reached an all-time high, while pollution per engine has been greatly reduced. Engineers have learned that through computer control and careful monitoring of important variables, vehicle powerplants can be greatly improved. To develop a viable fuel cell, engineers need to accurately monitor the condition of the hydrogen stream, oxygen stream, output voltage, and current. To optimize a fuel cell, not only are the flow and pressure of the hydrogen and oxygen monitored, but also the humidity and temperature of the gas streams. Knowing the voltages of the individual membranes can enable an engineer to read the health of a fuel-cell stack and control the output resistance to map the power densities of the stacks. To improve the 86 MARCH 2001 aei ments, who are creating hardware and software that permit more expedient development of fuel-cell technology. Hydrogenics has developed three test systems that permit characterization of either single cells or stacks of cells. By using National Instruments data-acquisition and control hardware in its systems, Hydrogenics is able to incorporate most of the desired measurement and safety options required by scientists. Although the overall goals of research and development, manufacturing, and operations vary, their need to monitor and control fuel cells is similar. For R&D, testing is done to characterize and optimize energy output as well as extend the life and robustness of the stacks. In design validation, the main goal is to optimize the design in preparation for mass production and to reduce the overall cost of the stack without reducing the efficiency. For manufacturing applications, the stacks are monitored to ensure they meet the engineer’s specifications. In actual use, monitoring is essential to a stack’s life and operation. Fortunately, different stages of fuel-cell implementation have similar needs of a well-designed tester to accommodate the applications. PEM fuel cells share the characteristics of requiring humidified hydrogen and oxygen and generating electricity with a byproduct of water. Although water is a desired output in the space program, the only output automotive scientists are truly interested in is electrical (current and voltage). Parameters that control the production of this power include gas-stream temperature, pressure, humidity, and flow rates. The stack’s individual cell voltages are measured and the overall stack temperature is monitored and controlled using active cooling. In as seen in Fuel-cell testing (140-175°F) to produce energy efficiently. This temperature is monitored for goals such as variation and correlation to power output. Thermocouples Item Channel type Signal conditioning and thermistors are good sensors for monitoring Voltage Analog input Isolation, attenuation both the stack temperature and the temperature Current Analog input Scaling attenuation of the incoming reactant gas streams. In many apPressure Analog input Scaling plications, the gas streams are at elevated presHumidity Analog input Scaling sures, which are monitored and managed. PresFlow rate Counter input Scaling sure is measured with a pressure transducer and Temperature Analog input Scaling, amplification, excitation signal conditioning, and the flow rate is measured Emergency shutoff Digital output Switching with a flowmeter that outputs pulses at a rate proNitrogen purge Digital output Switching portional to the gas flow rate. These pulses are then Pressure valves Analog output Amplification monitored by a counter timer board and scaled by Heater and fans GPIB or digital output Switching (with digital output) software into a flow rate. Electronic regulators can Load GPIB or digital output Switching (with digital output) control the pressure and flow via 4-20 mA inputs that are supplied by the test stand. many applications, the load resistance is variable, allowing enOne of the final challenges in a fuel-cell test stand is the gineers to develop tafel plots (voltage/current density plots measurement and control of gas-stream humidities. The water that indicate the power and efficiency of a stack or cell). A fuelflow in a cell is critical to its operation, and each membrane cell tester should be able to monitor and control all of these must remain hydrated to maintain its protonic conductivity. If parameters as well as measure and log the voltage and current a cell becomes too dry, the membranes are prone to damage. If outputs of the stack. the membrane floods, the transport of reactants is reduced and Consider the output of fuel cells: voltage and current. In a a dramatic drop in overall system performance occurs. Theretypical fuel-cell application, a known load is applied to the fuel fore, proper humidification control and monitoring is essencell to control output voltage and current. When the voltage tial to the operation of a PEM fuel cell. One way to monitor the output of a fuel cell increases, the output current decreases. humidity is through an electric humidity sensor that outputs The operating load of a fuel cell is a balance between the maxi4-20 mA current at a level proportional to the humidity. A voltmum power output and the maximum efficiency. For example, age input channel of the tester can then read this signal. a PEM was used by Virginia Tech’s hybrid-electric Chevy LuAlong with monitoring, control is also required to conduct mina for the 1999 Future Car Challenge. An Energy Partners fuel-cell testing. Almost all of the monitored items need to be fuel-cell stack was used, which created a range of 60-100 V dc. Under load with Table 2 current flowing, the output per cell would Fuel-cell Testing Hardware Components drop from 1 V to as low as 0.6 V per cell. Item Description Knowing the voltage of each individual PC/PXI controller Performs the test execution and data storage membrane allowed Virginia Tech to PC/PXI chassis Houses controller and I/O components closely monitor the health of its stack. Multifunction I/O Performs the analog to digital conversion and controls the conditioning If one cell exhibits a different potenRelays Routes power output tial, it is an indication of a problem with Analog output Controls pressure valves the cell, including incorrect temperature, Isolated/amplified analog input Monitors voltage and current under hydration, or flooding. The voltage Isolated thermocouple input Monitors temperature from thermocouples from each cell or group of cells is moniIsolated digital output Controls shutoff, bypass, and purge valves tored to operate, test, or design a fuel cell Programmable load Absorbs power output of fuel cell properly. By measuring a group of cells, Mass flow controller Controls gas flow the channel count and wiring requireFixturing/piping Routes gases into and out of fuel cell ments can be reduced while still monitoring the health of the cells. While each group of cells may reach up to 10 V in a PEM fuel cell, the controlled for repeatable tests. To control gas-stream pressures, membranes are stacked together to yield higher voltages. Beanalog output channels from the tester set the electrically varicause the stack can reach over 100 V, the tester must not only able pressure valves. Digital output lines provide the control have many channels that are capable of reading 10 V per chanfor emergency shutoff, purge output, and bypass valves. Gennel, but also maintain isolation of hundreds of volts between eral Purpose Interface Bus (GPIB) or analog output is used to the first and last cell in the stack. control the heaters and fans used for temperature control. In Obviously, simply monitoring the voltage is not sufficient addition, a programmable load is used to change the resistance to characterize and control a fuel cell. Current output is anseen by the fuel cell. One way a tester can accomplish this other item that is monitored. Because the current output can change is with a GPIB-controlled load device or by using digibe very high, it is usually monitored using the Gaussian effect. tal relays to connect various resistors in parallel. In the first This method allows engineers to unobtrusively monitor the curmethod, a stand-alone box is instructed, via GPIB, to change rent flowing through a wire; it requires signal conditioning and the loads placed on the fuel cell. The second option uses relays scaling to convert the data back into a current reading. PEM and switches different loads in and out. To vary the humidity, fuel cells typically require temperatures in the range of 60-80°C the water flow rate for the humidifier is adjusted. Table 1 Fuel-cell Parameters to be Monitored and Controlled aei MARCH 2001 87 as seen in Fuel-cell testing Components of a fuel-cell tester The major complication in the development of a true “turnkey” solution to fuel-cell testing has always been the mercurial needs of scientists due to the rapid evolution of fuel cells. As new advances are made in fuel-cell development, researchers need additional measurement data that was not always anticipated in the original design. One very clear example is in the trend toward higher stack voltages and more cells. For accurate monitoring of a cell stack, it is important to track the voltage of the individual cells. With an output potential of 0.6-1.0 V per cell, a 100-V stack will need up to 100 isolated analog inputs. Instead more robust form factor and operating system (OS) offers benefits for the demands of fuel-cell design testing. A choice that has gained support in recent years is a PXI or Compact PCI, which offers PC capabilities in a rugged and modular form factor. These can be outfitted with a real-time OS that controls data-acquisition and safety features of the test stand. The highest level of the control software is the test executive. This supervisory level piece of software calls individual test routines, indicates pass/fail, and generates results. The next level is the test routine software. For reliability purposes, the test routine would run on the non-Windows realtime operating system. An ideal architecture for the routine software would promote modularity and ease of modification, which is important because the procedures for testing fuel cells are evolving along with the technology itself. Test systems built around test executive and graphical programming software are under development and will retain the ability for future modification and run out of the box. In the testing hardware, I/O components that can digitize signals for the PC are needed. Testers equipped with a multifunction I/O board can scan many channels at both low and high rates. This ability allows engineers to monitor steady-state and transient voltage, current levels produced by the fuel cell, and stack operating parameters. Signal conditioning handles the conversion of current, pressure, and temperature to voltages. In addition to computer and data-acquisition cards, there are a programmable load, a humidification system, gas flow controllers, and a stack temperature controller. The last hardware element is the fixturing. To avoid ionic contamination of the cell membranes, 316 SS, Teflon, or titanium is often used in the water, hydrogen, and oxygen piping. For the same reason, all the water used for cooling and humidification must be deionized before introduction into the stack. Continued evolution Figure 3. Hydrogenics’ fuel-cell test system uses National Instruments’ FieldPoint distributed I/O to monitor and control fuel-cell testing. of building a black-box tester, many companies are working to develop modular systems that will allow researchers to modify the design as their testing needs change. Central to this flexible design is a virtual interface and virtual instrumentation that will allow the addition and modification of input parameters and of stored data. Almost all testers today use a computer interface to collect, analyze, display, and store data. Robust testers, such as Hydrogenics’ systems, also incorporate a stable, real-time operating system for the data collection and for the nitrogen purge safety systems. Hardware and software Although the needs of PEM test engineers are challenging, many components from the test and measurement industry are equipped to handle the task. The hardware components of a test stand include the controller, the fixturing, and the transducers. A popular choice for the controller is a PC-based one. This method offers the advantage of leveraging PC advancements such as speed, memory, and upgradability. A 88 MARCH 2001 aei Fuel cells, as a developing technology, show promise to become one of the most efficient and clean energy-producing sources available. In addition to providing on-demand energy without the CO and NOx typically associated with combustion, they also promise to reduce greenhouse gas emissions with their CO2-free exhaust. However, before they are practical for widespread use, great developmental strides need to be accomplished to reduce size and increase energy yield. Test systems that have the capability to make all relevant measurements while providing the flexibility to incorporate new procedures and calculations are critical to this development. A test platform based on PC technology with the open architecture of the PXI/Compact PCI form factor provides a good test foundation by blending mainstream PC technologies and a rugged reliability while delivering a high degree of modularity. With millions of dollars being invested each year and interest in fuelcell development being propelled by environmental, governmental, and consumer pressures, the fuel cell will continue to evolve at a rapid pace, and virtual-instrumentation-based controllers will test it every changing step of the way. Information for this article was supplied by Dave Wilson, Director, Automotive Market Development, and Todd Walter, Application Engineer, National Instruments.