Poisson`s ratio

... decrease. Ph always has positive value and the negative sign in the compensation (R.H.S.) keeps this relation valid. A material that has a large bulk modulus could be imagined to consist of very tightly bound spring and ball materials which will quickly transmit a wave. Ideally, elastic deformation ...

... decrease. Ph always has positive value and the negative sign in the compensation (R.H.S.) keeps this relation valid. A material that has a large bulk modulus could be imagined to consist of very tightly bound spring and ball materials which will quickly transmit a wave. Ideally, elastic deformation ...

Finite Element Analysis of Thermal Stresses in a Pad-Disc Brake System (a Review)

... in the radial direction were determined. The obtained outcomes were compared with the experimental results carried out using thermography techniques and thermocouples. The problem of the crack initiation and growth in the rail wheels subjected to cyclic thermal loads due to heating and cooling durin ...

... in the radial direction were determined. The obtained outcomes were compared with the experimental results carried out using thermography techniques and thermocouples. The problem of the crack initiation and growth in the rail wheels subjected to cyclic thermal loads due to heating and cooling durin ...

fracture analysis of surface- and through-cracked

... titanium weldment, and aluminum alloy tested at room and cryogenic temperature were analyzed according to equation (9). Wide ranges of crack-depth to crack-half-length ratio (a/c = 0.08 to 1.4) and crack-depth to specimen-thickness ratio (a/t = 0.05 to 1.0) were considered. The material thickness ra ...

... titanium weldment, and aluminum alloy tested at room and cryogenic temperature were analyzed according to equation (9). Wide ranges of crack-depth to crack-half-length ratio (a/c = 0.08 to 1.4) and crack-depth to specimen-thickness ratio (a/t = 0.05 to 1.0) were considered. The material thickness ra ...

The Usability of Rock-Like Materials for Numerical Studies on Rocks

... failure behavior of different rocks. In order to model the failure behavior of rock material, researchers take advantageous of different techniques and software. But, the majority of all these instruments are based on distinct element method (DEM). For modeling the failure behavior of rocks, and so ...

... failure behavior of different rocks. In order to model the failure behavior of rock material, researchers take advantageous of different techniques and software. But, the majority of all these instruments are based on distinct element method (DEM). For modeling the failure behavior of rocks, and so ...

INFLUENCE OF THE PROPERTY OF HOLE ON STRESS

... of isotropic plates by adjusting the properties of holes. The present study may provide designers an efficient way to estimate the strength of the plate structures with holes. ...

... of isotropic plates by adjusting the properties of holes. The present study may provide designers an efficient way to estimate the strength of the plate structures with holes. ...

the stress free building concept

... simple fastening and drywall system to create “stress free buildings”. It doesn’t matter if you are building a single family home or a 350 unit mixed use complex, this system works! By top plating all the bearing walls with standard 2X material and reducing the interior non‐bearing wall top plate ...

... simple fastening and drywall system to create “stress free buildings”. It doesn’t matter if you are building a single family home or a 350 unit mixed use complex, this system works! By top plating all the bearing walls with standard 2X material and reducing the interior non‐bearing wall top plate ...

SIKO The Safety Design Concept

... performance required today calls for design solutions which lie much closer to the physical limits of the turbochargers. The load factor for the rotating components in particular has ...

... performance required today calls for design solutions which lie much closer to the physical limits of the turbochargers. The load factor for the rotating components in particular has ...

in situ biomechanical response of the lumbar spine due to external

... the occurring interdisciplinary phenomena entailing hundreds of muscle reactions activated during every day activities. FE is valuable for elucidating in situ stress development of the spine, indicating regions susceptible to critical loading. The reflection of active musculature during modelling is ...

... the occurring interdisciplinary phenomena entailing hundreds of muscle reactions activated during every day activities. FE is valuable for elucidating in situ stress development of the spine, indicating regions susceptible to critical loading. The reflection of active musculature during modelling is ...

Chapter 9

... It is possible to change the shape or size (or both) of an object through the application of external forces When the forces are removed, the object tends to its original shape ...

... It is possible to change the shape or size (or both) of an object through the application of external forces When the forces are removed, the object tends to its original shape ...

Properties of TiAl6V4 alloy parts produced by selective

... minimum at the stage of the powder-layer consolidation. This requires a careful process optimization procedure to obtain a high quality material [1]. For this reason more than 60 test samples were produced by SLM from TiAl6V4 powder varying different scan parameters: laser power, scanning rate, hatc ...

... minimum at the stage of the powder-layer consolidation. This requires a careful process optimization procedure to obtain a high quality material [1]. For this reason more than 60 test samples were produced by SLM from TiAl6V4 powder varying different scan parameters: laser power, scanning rate, hatc ...

effect of thermal stresses along crack surface on ultrasonic response

... !!!!!The crack opening was monitored by a video camera during the loading. Figure 13 shows the crack opening measured from the video image as a function of time together with UT amplitude and calculated strains. The crack closes during heating (surface under compressive strains) and opens during coo ...

... !!!!!The crack opening was monitored by a video camera during the loading. Figure 13 shows the crack opening measured from the video image as a function of time together with UT amplitude and calculated strains. The crack closes during heating (surface under compressive strains) and opens during coo ...

Chapter 6: Mechanical Properties

... We Compute sT = KeTn to complete our True Stress True Strain plot (plastic data to necking) • Take Logs of both sT and eT • Regress the values from Yielding to ...

... We Compute sT = KeTn to complete our True Stress True Strain plot (plastic data to necking) • Take Logs of both sT and eT • Regress the values from Yielding to ...

A Novel 3D Finite Element Simulation Model for

... Compressive residual stresses are induced during shot peening in the surface near regions of treated components and are balanced by an almost constant tensile residual stress field in greater depths (Menig, 2000). For bulky components the tensile stresses are small because of the available thickness ...

... Compressive residual stresses are induced during shot peening in the surface near regions of treated components and are balanced by an almost constant tensile residual stress field in greater depths (Menig, 2000). For bulky components the tensile stresses are small because of the available thickness ...

Hints

... (a) (20%) Consider the amount of strain following the onset of yielding, but before the point of fracture. If this portion of the stress-strain curve is large relative to the elastic portion of the curve, it is a ductile material. (b) (20%) The stiffest material is the one with the greatest slope in ...

... (a) (20%) Consider the amount of strain following the onset of yielding, but before the point of fracture. If this portion of the stress-strain curve is large relative to the elastic portion of the curve, it is a ductile material. (b) (20%) The stiffest material is the one with the greatest slope in ...

Articular Cartilage Notes - Biomechanics and Biol+

... Seems reasonable to ignore the time dependency and approximate cartilage response using short time properties An assumption is cartilage behaves elastically when subjected to fast load application o Ideally this is only true after a short time period of load application before the fluid in the carti ...

... Seems reasonable to ignore the time dependency and approximate cartilage response using short time properties An assumption is cartilage behaves elastically when subjected to fast load application o Ideally this is only true after a short time period of load application before the fluid in the carti ...

Chapter 5 - Stress in Fluids

... The only material property of the fluid we have so far discussed is the density. In the last chapter we introduced the rate of deformation or rate of strain tensor. The distinguishing characteristic between fluids and solids is that fluids can undergo unlimited deformation and yet maintain its integ ...

... The only material property of the fluid we have so far discussed is the density. In the last chapter we introduced the rate of deformation or rate of strain tensor. The distinguishing characteristic between fluids and solids is that fluids can undergo unlimited deformation and yet maintain its integ ...

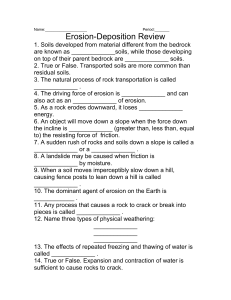

Erosion Review

... Erosion-Deposition Review 1. Soils developed from material different from the bedrock are known as _____________soils, while those developing on top of their parent bedrock are _____________ soils. 2. True or False. Transported soils are more common than residual soils. 3. The natural process of roc ...

... Erosion-Deposition Review 1. Soils developed from material different from the bedrock are known as _____________soils, while those developing on top of their parent bedrock are _____________ soils. 2. True or False. Transported soils are more common than residual soils. 3. The natural process of roc ...

Composites

... Much stronger than glass reinforced plastic (GRP) Has more than four times the tensile strength of the best steel alloys at just a quarter of the weight. Also has a better fatigue life Medium Density fibreboard: Made from wood waste (softwoods) in the form of wood chips These chips are sub ...

... Much stronger than glass reinforced plastic (GRP) Has more than four times the tensile strength of the best steel alloys at just a quarter of the weight. Also has a better fatigue life Medium Density fibreboard: Made from wood waste (softwoods) in the form of wood chips These chips are sub ...

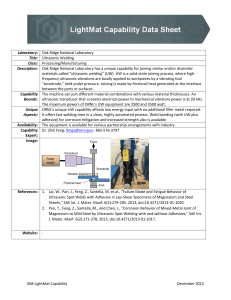

068_ORNL

... materials called “ultrasonic welding” (UW). UW is a solid-state joining process, where highfrequency ultrasonic vibrations are locally applied to workpieces by a vibrating tool “sonotrode,” held under pressure. Joining is made by frictional heat generated at the interface between the parts or surfac ...

... materials called “ultrasonic welding” (UW). UW is a solid-state joining process, where highfrequency ultrasonic vibrations are locally applied to workpieces by a vibrating tool “sonotrode,” held under pressure. Joining is made by frictional heat generated at the interface between the parts or surfac ...

abstract

... of the crack surface Γc . According to Eq. (1), crack propagation is understood as a competition between surface energy and energy released in the bulk. Although the global criterion (1) eliminates the aforementioned problems associated with Griffith’s theory, it induces some new difficulties. From ...

... of the crack surface Γc . According to Eq. (1), crack propagation is understood as a competition between surface energy and energy released in the bulk. Although the global criterion (1) eliminates the aforementioned problems associated with Griffith’s theory, it induces some new difficulties. From ...

Lecture 8a - States of Matter

... The change in length of a stretched object depends not only on the applied force, but also on its length, cross-sectional area and the material from which it is made. The material factor, E, is called the elastic modulus or Young’s modulus, and it has been measured for many materials. ...

... The change in length of a stretched object depends not only on the applied force, but also on its length, cross-sectional area and the material from which it is made. The material factor, E, is called the elastic modulus or Young’s modulus, and it has been measured for many materials. ...

Slide 1

... Beam supported by a pin and cable. A uniform beam, 2.20 m long with a mass m = 25.0 kg, is mounted by a pin on a wall. The beam is held in a horizontal position by a cable that makes an angle q = 30.0o. The beam supports a sign of mass M = 280 kg suspended from its end. Determine the components of t ...

... Beam supported by a pin and cable. A uniform beam, 2.20 m long with a mass m = 25.0 kg, is mounted by a pin on a wall. The beam is held in a horizontal position by a cable that makes an angle q = 30.0o. The beam supports a sign of mass M = 280 kg suspended from its end. Determine the components of t ...

Chapter 1 - Dr. ZM Nizam

... The elastic limit is the limit beyond which the material will no longer go back to its original shape when the load is removed, or it is the maximum stress that may be developed such that there is no permanent or residual deformation when the load is entirely removed. Yield Point/ Yield Strength Yie ...

... The elastic limit is the limit beyond which the material will no longer go back to its original shape when the load is removed, or it is the maximum stress that may be developed such that there is no permanent or residual deformation when the load is entirely removed. Yield Point/ Yield Strength Yie ...

Identifying Failures and Ensuring Quality of Plastic Materials

... the life of the product. In this case study, fasteners cracked over time while in service. The observed features of the failure indicated a slow crack growth or creep rupture under the load stress to which the parts were subjected. Upon further investigation it was determined that the failed parts a ...

... the life of the product. In this case study, fasteners cracked over time while in service. The observed features of the failure indicated a slow crack growth or creep rupture under the load stress to which the parts were subjected. Upon further investigation it was determined that the failed parts a ...

Mechanical Properties of Metals

... Typically slip planes are the most densely packed planes (less energy is required to move from one position to another), which are the farthest separated ...

... Typically slip planes are the most densely packed planes (less energy is required to move from one position to another), which are the farthest separated ...

Fatigue (material)

In materials science, fatigue is the weakening of a material caused by repeatedly applied loads. It is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. The nominal maximum stress values that cause such damage may be much less than the strength of the material typically quoted as the ultimate tensile stress limit, or the yield stress limit.Fatigue occurs when a material is subjected to repeated loading and unloading. If the loads are above a certain threshold, microscopic cracks will begin to form at the stress concentrators such as the surface, persistent slip bands (PSBs), and grain interfaces. Eventually a crack will reach a critical size, the crack will propagate suddenly, and the structure will fracture. The shape of the structure will significantly affect the fatigue life; square holes or sharp corners will lead to elevated local stresses where fatigue cracks can initiate. Round holes and smooth transitions or fillets will therefore increase the fatigue strength of the structure.