IOSR Journal of Electrical and Electronics Engineering (IOSR-JEEE) e-ISSN: 2278-1676,p-ISSN: 2320-3331,

... ignoring the VCC, RXD, and TXD pins (as long as the target device is self powered). The circuit is shown above. It is very simple, yet very effective. 2.2 Induction Motor An induction or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is ...

... ignoring the VCC, RXD, and TXD pins (as long as the target device is self powered). The circuit is shown above. It is very simple, yet very effective. 2.2 Induction Motor An induction or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is ...

File - ganesh subramanian

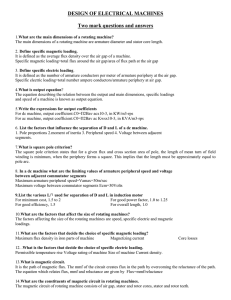

... 61. What is the cause of noise in transformer? The cause of noise in the transformer is mainly because of magneto-striction effect and also loosening of stampings and mechanical forces produced during working. 62.Why is the area of yoke of a transformer usually kept 15-20%more than that of core. By ...

... 61. What is the cause of noise in transformer? The cause of noise in the transformer is mainly because of magneto-striction effect and also loosening of stampings and mechanical forces produced during working. 62.Why is the area of yoke of a transformer usually kept 15-20%more than that of core. By ...

Electrical Testing at Elevated Frequency of Stator Cores and Exciter Circuits

... The measurement is performed at a frequency of 500 Hz, as significantly lower power is required at high frequency than at grid frequency (50 or 60 Hz) to generate equivalent magnetization losses in the stator core. However, since the stress on the insulation between the laminations is comparable, th ...

... The measurement is performed at a frequency of 500 Hz, as significantly lower power is required at high frequency than at grid frequency (50 or 60 Hz) to generate equivalent magnetization losses in the stator core. However, since the stress on the insulation between the laminations is comparable, th ...

Synchronous generators

... due to permanent magnets mounted in the rotor or this magnetic field is due to electromagnets mounted in the rotor and fed by a DC current. By controlling this DC current, the induction of this magnetic field can be controlled (which is not possible when using permanent magnets). Synchronous generat ...

... due to permanent magnets mounted in the rotor or this magnetic field is due to electromagnets mounted in the rotor and fed by a DC current. By controlling this DC current, the induction of this magnetic field can be controlled (which is not possible when using permanent magnets). Synchronous generat ...

4 Point Starter

... contact with studs 2, 3, 4 etc., thus gradually cutting off the series resistance from the armature circuit as the motor gathers speed. Finally when the starter handle is in 'RUN' position, the entire starting resistance is eliminated and the motor runs with normal speed. This is because back emf is ...

... contact with studs 2, 3, 4 etc., thus gradually cutting off the series resistance from the armature circuit as the motor gathers speed. Finally when the starter handle is in 'RUN' position, the entire starting resistance is eliminated and the motor runs with normal speed. This is because back emf is ...

A reconfigurable structure electronic commutator for a dual BLDC

... magnets. They are divided into brushlesss DC motors (BLDCM) and synchronous motors (PMSM) [11]. The differences between them result mainly from the construction of magnetic circuits. The way of controlling and forming the phase current is the most fundamental determinant of these machines’ classific ...

... magnets. They are divided into brushlesss DC motors (BLDCM) and synchronous motors (PMSM) [11]. The differences between them result mainly from the construction of magnetic circuits. The way of controlling and forming the phase current is the most fundamental determinant of these machines’ classific ...

Modeling of Interior Permanent Magnet Synchronous Motor using

... Permanent Magnets (PMs) eliminate the use of field exciting coils and slip rings for current conduction. Due to the absence of field winding inside the rotor, PM motors have low inertia. The field strength is so high that the motor volume can be reduced [4]. Further, since there is no copper loss on ...

... Permanent Magnets (PMs) eliminate the use of field exciting coils and slip rings for current conduction. Due to the absence of field winding inside the rotor, PM motors have low inertia. The field strength is so high that the motor volume can be reduced [4]. Further, since there is no copper loss on ...

SMJE 2103

... A 480V, 60Hz, 50hp, 3 phase induction motor is drawing 60A at 0.85 Pf lagging. The stator copper losses are 2 kW, and the rotor losses are 700W. The friction and windage losses re 600W, the core losses are 180W, and the stray losses are negligible. Find: a) The air gap power PAG b) The power convert ...

... A 480V, 60Hz, 50hp, 3 phase induction motor is drawing 60A at 0.85 Pf lagging. The stator copper losses are 2 kW, and the rotor losses are 700W. The friction and windage losses re 600W, the core losses are 180W, and the stray losses are negligible. Find: a) The air gap power PAG b) The power convert ...

ECE 371 SUSTAINABLE ENERGY SYSTEMS EXPERIMENT 3 INTRODUCTION TO SYNCHRONOUS GENERATORS

... 1. Learn to connect the dc machine (dynamometer) as a motor and the synchronous machine as a generator. 2. Gain an understanding of the relationship between the speed of prime-mover and the frequency of generated ac voltage. 3. Gain an understanding of the phase angle relationship between the phase ...

... 1. Learn to connect the dc machine (dynamometer) as a motor and the synchronous machine as a generator. 2. Gain an understanding of the relationship between the speed of prime-mover and the frequency of generated ac voltage. 3. Gain an understanding of the phase angle relationship between the phase ...

Heavy-Duty Truck Sytems Chapter 08

... alternator, voltage regulator, associated wiring, and the electrical loads of the chassis. • The purpose of the charging system is to recharge the batteries whenever necessary and to provide the current required to power the electrical components on the truck chassis. • A malfunction in the charging ...

... alternator, voltage regulator, associated wiring, and the electrical loads of the chassis. • The purpose of the charging system is to recharge the batteries whenever necessary and to provide the current required to power the electrical components on the truck chassis. • A malfunction in the charging ...

Commutator (electric)

A commutator is the moving part of a rotary electrical switch in certain types of electric motors and electrical generators that periodically reverses the current direction between the rotor and the external circuit. It consists of a cylinder composed of multiple metal contact segments on the rotating armature of the machine. The commutator is one component of a motor; there are also two or more stationary electrical contacts called ""brushes"" made of a soft conductor like carbon press against the commutator, making sliding contact with successive segments of the commutator as it rotates. The windings (coils of wire) on the armature are connected to the commutator segments. Commutators are used in direct current (DC) machines: dynamos (DC generators) and many DC motors as well as universal motors. In a motor the commutator applies electric current to the windings. By reversing the current direction in the rotating windings each half turn, a steady rotating force (torque) is produced. In a generator the commutator picks off the current generated in the windings, reversing the direction of the current with each half turn, serving as a mechanical rectifier to convert the alternating current from the windings to unidirectional direct current in the external load circuit. The first direct current commutator-type machine, the dynamo, was built by Hippolyte Pixii in 1832, based on a suggestion by André-Marie Ampère. Commutators are relatively inefficient, and also require periodic maintenance such as brush replacement. Therefore, commutated machines are declining in use, being replaced by alternating current (AC) machines, and in recent years by brushless DC motors which use semiconductor switches.