Learn-to-Solder Exercise: Practice Flasher Circuit

... Change 1 – solder in a socket then insert the 555 timer chip – don’t solder chip directly Change 2 – strip wires for battery snap and/or add a disconnect header, if requested ...

... Change 1 – solder in a socket then insert the 555 timer chip – don’t solder chip directly Change 2 – strip wires for battery snap and/or add a disconnect header, if requested ...

Safety Rules for Soldering Soldering Techniques

... heat transfer between the tip and the components. The cleaning sponge should be soaking wet. Quickly run the soldering tip over the wet sponge to get rid of excess solder. 4. Clean the contact surfaces of the metal parts if necessary. Scrape off oxides with a utility blade. In some cases, it is easi ...

... heat transfer between the tip and the components. The cleaning sponge should be soaking wet. Quickly run the soldering tip over the wet sponge to get rid of excess solder. 4. Clean the contact surfaces of the metal parts if necessary. Scrape off oxides with a utility blade. In some cases, it is easi ...

Learn-to-Solder Exercise: Practice Flasher Circuit

... Place the 555 chip on the side of the PCB opposite the metal traces. Be very careful to get orientation correct. ...

... Place the 555 chip on the side of the PCB opposite the metal traces. Be very careful to get orientation correct. ...

Building a Flasher Circuit (AKA Learn to Solder Exercise)

... Place the 555 chip on the side of the PCB opposite the metal traces. Be very careful to get orientation correct. ...

... Place the 555 chip on the side of the PCB opposite the metal traces. Be very careful to get orientation correct. ...

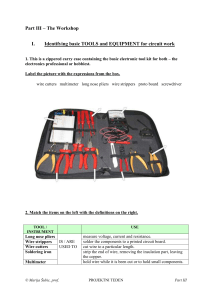

Part III – the workshop

... wire cutters multimeter long nose pliers wire strippers proto board screwdriver ...

... wire cutters multimeter long nose pliers wire strippers proto board screwdriver ...

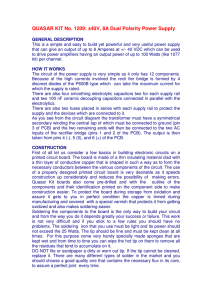

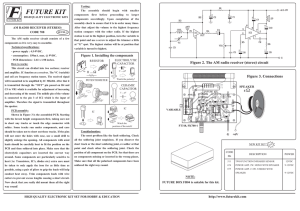

FUTURE KIT

... with the lowest height components first, taking care not to short any tracks or touch the edge connector with solder. Some tracks run under components, and care should be taken not to short out these tracks. If the pins will not enter the holes with ease, use a small drill to slightly enlarge the op ...

... with the lowest height components first, taking care not to short any tracks or touch the edge connector with solder. Some tracks run under components, and care should be taken not to short out these tracks. If the pins will not enter the holes with ease, use a small drill to slightly enlarge the op ...

chemicals

... consisting of a solution of special rosin in alcohol. Contains no traces of acids or chlorides and is completely safe to use on even the most delicate electronic equipment. Will work also with Lead Free solder. 2 fl. oz. Bottle Part No. 10-4202 Part No. 10-4216 16 fl. oz. Bottle ...

... consisting of a solution of special rosin in alcohol. Contains no traces of acids or chlorides and is completely safe to use on even the most delicate electronic equipment. Will work also with Lead Free solder. 2 fl. oz. Bottle Part No. 10-4202 Part No. 10-4216 16 fl. oz. Bottle ...

Document

... Board stuffing is the term applied to loading circuit boards with their component parts. Today, board stuffing is automated. It’s done by pick and place robots. The DIP and other through-hole mounted components do not work well with today’s automated assembly techniques. ...

... Board stuffing is the term applied to loading circuit boards with their component parts. Today, board stuffing is automated. It’s done by pick and place robots. The DIP and other through-hole mounted components do not work well with today’s automated assembly techniques. ...

Surface-mount technology

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). An electronic device so made is called a surface-mount device (SMD). In the industry it has largely replaced the through-hole technology construction method of fitting components with wire leads into holes in the circuit board. Both technologies can be used on the same board for components not suited to surface mounting such as large transformers and heat-sinked power semiconductors.An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.